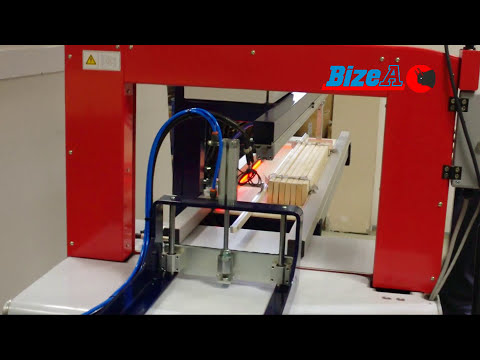

"LADE" device for installing bed mattress inserts

Length of strips 600 – 1400 mm

Strip thickness 10 – 14 mm

Tape width minimum 15 mm

Staple type: 380 (BIZON ; BeA)

Two BeA Autotec K380/08-14 modular staplers, series 231 with 5,000 magazines. staples 380/8

Working speed steplessly controlled 0.0-16.0 m/min

Working pressure of compressed air 0.55 – 0.7 MPa

Air demand approx. 320 l/min

Supply voltage:

– tamping device 230 V, 50 Hz

– belt conveyor 400V, 50 Hz

Installed power 1.5 kW

Dimensions:

– nailing machine 2210×2200×2200 mm

– belt conveyor 3000x1530x92 mm